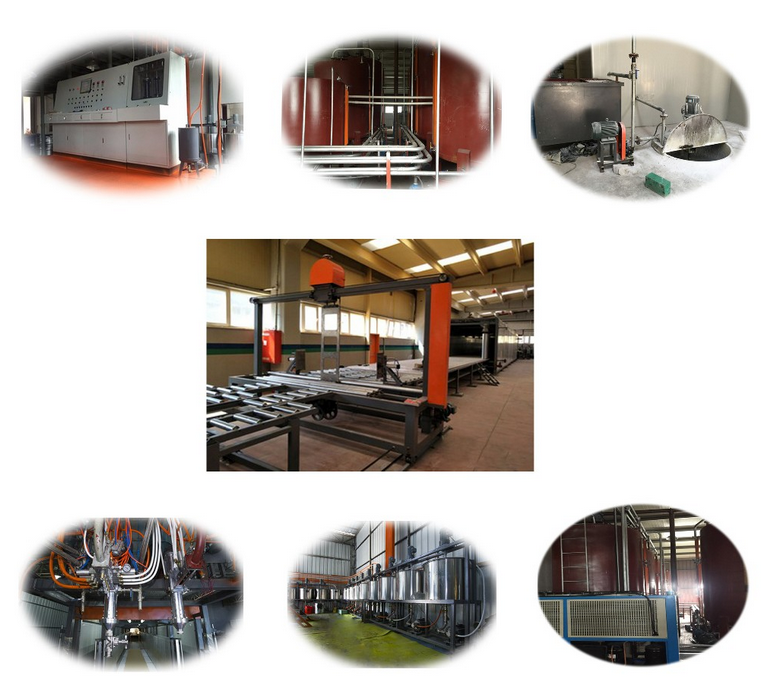

Dongguan Zehui machinery equipment co., ltd is professional mechanical Sponge machinery, Foam machine

equipment, advanced equipment and strong technical force, brought

together for many years sponge machine, foam machinery and Foam

machine of valuable experience, learning from international

advanced level products, integrated with industry experience,

adhere to independent innovation, "exploration, innovation,

durability, trustworthy, customer first "for the purpose of

pursuing a" people-oriented, scientific development, the pursuit of

excellence, "the core values of" innovation and strengthen the

country, to a fine sincerity, harmony and win-win "spirit of

enterprise. The company has always been adhering to the precise,

stable and efficient mechanical design principles, honesty,

responsible for business philosophy, "not the best, only better."

Our production of ZHF-2O17 Automatic sponge foam machinery, non-stop change the formula,

do not measure flow, aniseed error 0.01-0.03KG, small material

error 1-3G; the equipment to the British level rebound, slow

rebound, slow rebound shoes, electronic cotton , Bust cotton-based,

anti-yellowing degree can be achieved 3--5 class international

standards, the hardness from 20-200, plus powder 10-250%, the

lowest density 6-100, all kinds of shoes, furniture sponge; with

plant party requesting a variety of formulations, on behalf of the

training of senior foam division.

Our business philosophy is:

honesty

- honesty is the rise of enterprise road. Employee loyalty,

companies gain the trust of customers. Shoulder social

responsibilities with integrity, honesty and win-win to build a

bridge.

Customer first

- the future of enterprise customers with the customer is always

God. The client's ideas and the pursuit of reality is the greatest

satisfaction.

Transformation and innovation

- the trend of the ever-changing market, customer needs constantly

updated. Transformation and innovation to adapt to the market and

guide the market, business intelligence is the external expression.

Never-ending transformation and innovation are to promote business

vitality and the driving force.

Sophisticated management

- successful management is to operate every aspect of careful and

well-linked. Product quality is let off the production process of

every nuance. So exquisite soul quality management, quality

products is the materialization of the corporate culture.

Wholeheartedly welcome new and old customers coming negotiations,

the Department would like to be your most loyal partners, work

together for common off!

The products of our company have exported to all over the world

(including Europe, the United States, the Middle East, Southeast

Asia, Sudan, Indonesia, Vietnam, Kenya, etc.), with a large volume

of business, the company develops rapidly with a group of

outstanding service and technical personnel.

Welcome new and old customers at home and abroad come to our

company for business negotiation, Zehui is willing to become your

most faithful partner, and makes a win-win situation hand in hand!

https://youtu.be/qIPkDIUD0bA